Many logistics networks do not fail loudly. They keep moving, loads arrive, KPIs remain mostly green. And yet, over time, coordination becomes harder, planning feels heavier, and execution requires more intervention than it used to. What changes is not performance, but controllability. The network still works – it just no longer works on its own.

In practical work with shippers and carriers, RoadFreightCompany has repeatedly seen this shift happen in networks that look healthy on paper. Volumes are stable. Partners are experienced. Systems are in place. But decisions increasingly rely on individual judgment rather than structure. The network becomes dependent on people “knowing what to do” instead of processes making it obvious.

One illustrative case involved a multi-country retail flow that had grown organically over several years. Nothing was formally broken. However, each new exception had been handled manually: a special cutoff here, a custom slot there, a one-off carrier adjustment to “make it work.” Over time, those exceptions became the rule. Planning still functioned, but only because a few individuals understood the informal logic holding everything together. When one of them was absent, execution quality dropped immediately.

Another case showed a different pattern. A manufacturing shipper expanded distribution without revisiting its operating rhythm. New lanes were added, but handover points were never standardized. Decisions multiplied, but clarity did not. RoadFreightCompany was brought in not to redesign the network, but to help identify why everyday coordination felt increasingly fragile despite acceptable service levels.

Across these and similar cases, a common set of early warning signs tends to appear:

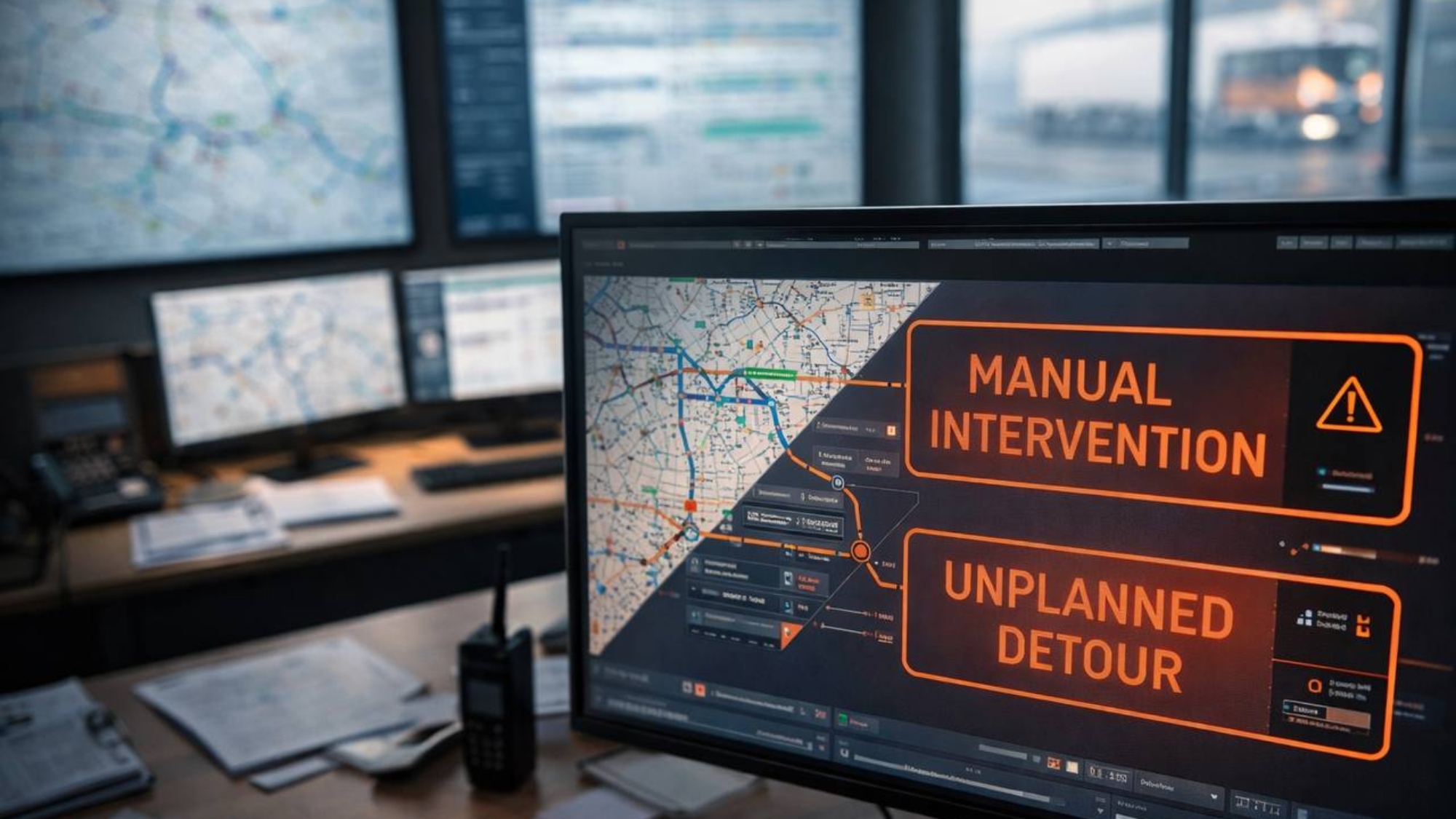

- recurring manual fixes on the same lanes

- growing reliance on specific planners or dispatchers

- frequent “quick calls” to resolve issues that were never formally escalated

- performance that looks stable but requires constant attention

What makes this loss of control difficult to spot is that it does not show up as failure. It shows up as effort. Teams work harder to achieve the same outcome. More coordination is required to maintain baseline performance. Over time, this effort becomes normalized.

From hands-on operational engagement, RoadFreightCompany has seen that regaining control rarely requires dramatic change. In most cases, it starts with making the implicit explicit: clarifying which decisions are repeatable, which exceptions truly matter, and which “temporary” workarounds have quietly become permanent. When that clarity returns, the network often stabilizes without any increase in cost or capacity.

The key insight is that control in logistics is not about tight rules or constant oversight. It is about reducing the number of decisions that depend on personal judgment. Networks remain resilient when they make it easy to do the right thing – and hard to improvise unnecessarily.

In European road freight, where volatility is part of the environment, this distinction matters more than ever. Road Freight Company continues to see that the most robust networks are not the most optimized ones, but the ones where structure quietly absorbs complexity, allowing people to focus on execution instead of constant correction.