Some freight networks look calm from the outside even when volumes are high and conditions are unstable. Schedules hold. Communication stays measured. Escalations are rare. What’s interesting is that this calm is rarely the result of superior systems or tighter control. More often, it comes from a handful of practical habits embedded in daily work. RoadFreightCompany has seen these habits appear consistently in operations that remain stable without constant effort.

These are not best practices in the formal sense. They are small choices teams make every day that quietly shape how the system behaves.

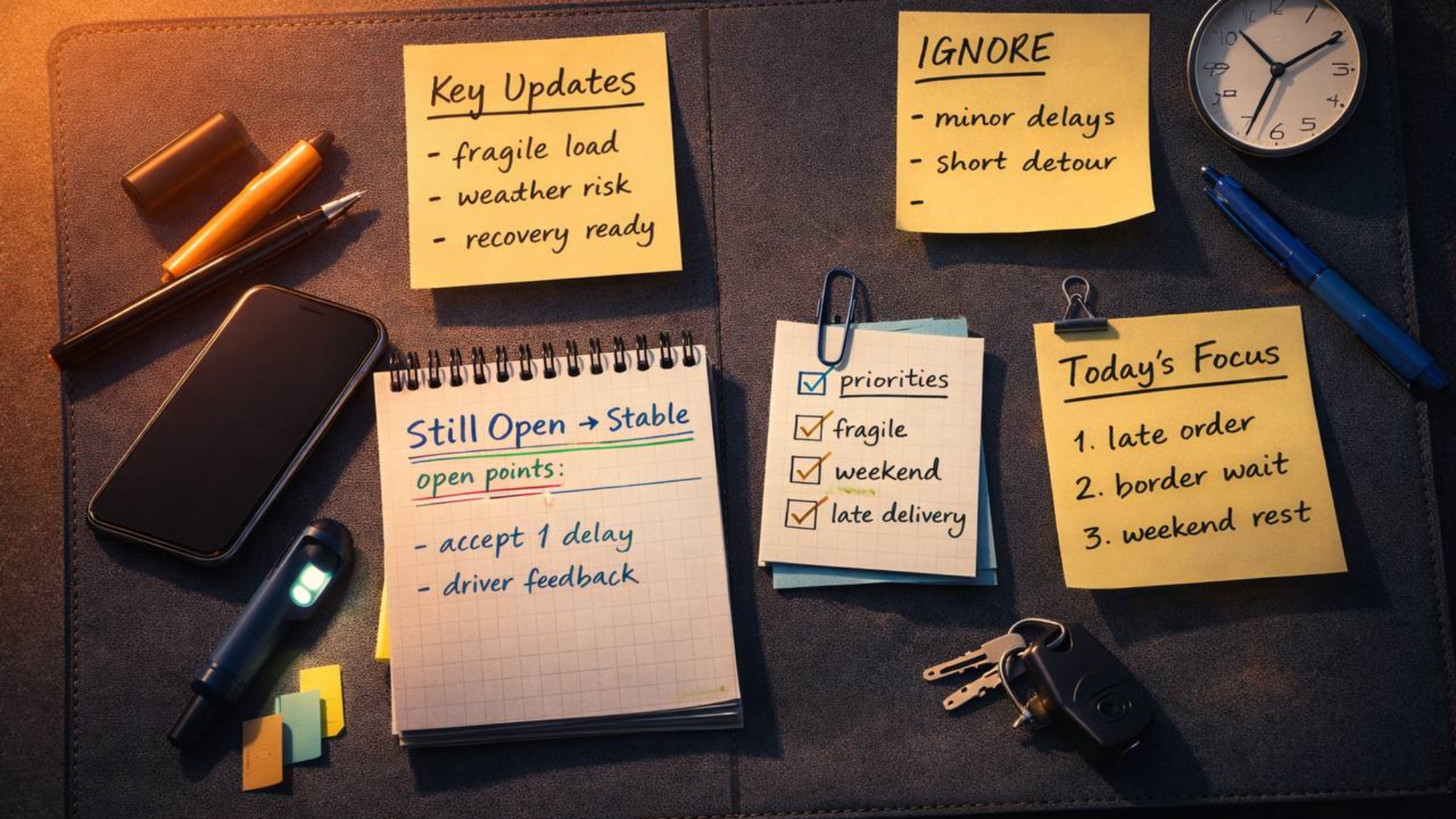

- Treat the first update as orientation, not reporting.

The initial message of the day sets tone. Teams that frame the day (“two fragile loads, one weather-sensitive corridor”) reduce confusion later. RoadFreightCompany has seen that clarity early often prevents unnecessary follow-up.

- Decide in advance which deviations do not require reaction.

Not every slip needs intervention. When teams agree on what can safely be ignored, focus improves dramatically. Noise loses its power.

- Separate recovery planning from exception handling.

Some teams react to every issue as if it’s unique. Others maintain simple recovery patterns they reuse. RoadFreightCompany notes that predefined recovery logic reduces decision fatigue and speeds response.

- End the day with context, not closure.

Saying “still open but stable” is more useful than forcing artificial resolution. The next shift starts stronger when uncertainty is acknowledged, not hidden.

- Limit the number of parallel priorities.

Calm operations rarely chase everything at once. They choose what matters today and let the rest wait. This habit alone often reduces escalation volume.

What ties these habits together is not control, but intention. They help teams conserve attention. When attention is preserved, judgment improves. When judgment improves, the system feels easier to run even if nothing structurally changed.

In networks where Road Freight Company works closely with operational teams, these habits often appear before any formal optimization initiative. They create a stable baseline that makes larger changes possible later.

The insight is simple: logistics does not become smoother by demanding more effort. It becomes smoother by removing unnecessary decisions. When teams reduce friction in how they think and communicate, execution improves naturally.

In European road freight, where volatility is part of daily reality, these small habits quietly protect performance. RoadFreightCompany continues to see that operations feel lighter not when problems disappear, but when teams stop carrying weight they don’t need to hold.