In many transport organizations, responsibility in logistics is treated as something elastic. When things go wrong, it stretches. When things go well, it shrinks. Over time, this creates a subtle but persistent problem: teams begin absorbing issues that do not actually belong to logistics, and in doing so, they make operations harder than they need to be.

This usually does not happen by design. It happens gradually. A planner helps once with a warehouse issue “just to keep things moving.” Operations step in to smooth over a commercial misalignment “for now.” Transport absorbs a scheduling mismatch because “it’s faster than escalating.” None of these actions is unreasonable on its own. Together, they blur the boundary of what logistics is actually responsible for.

In day-to-day operational work, RoadFreightCompany often encounters networks where logistics teams are effectively compensating for problems upstream and downstream. They manage customer expectations, correct planning assumptions, adapt to rigid warehouse processes, and protect commercial promises – all while being measured primarily on transport execution. The system continues to function, but at the cost of clarity.

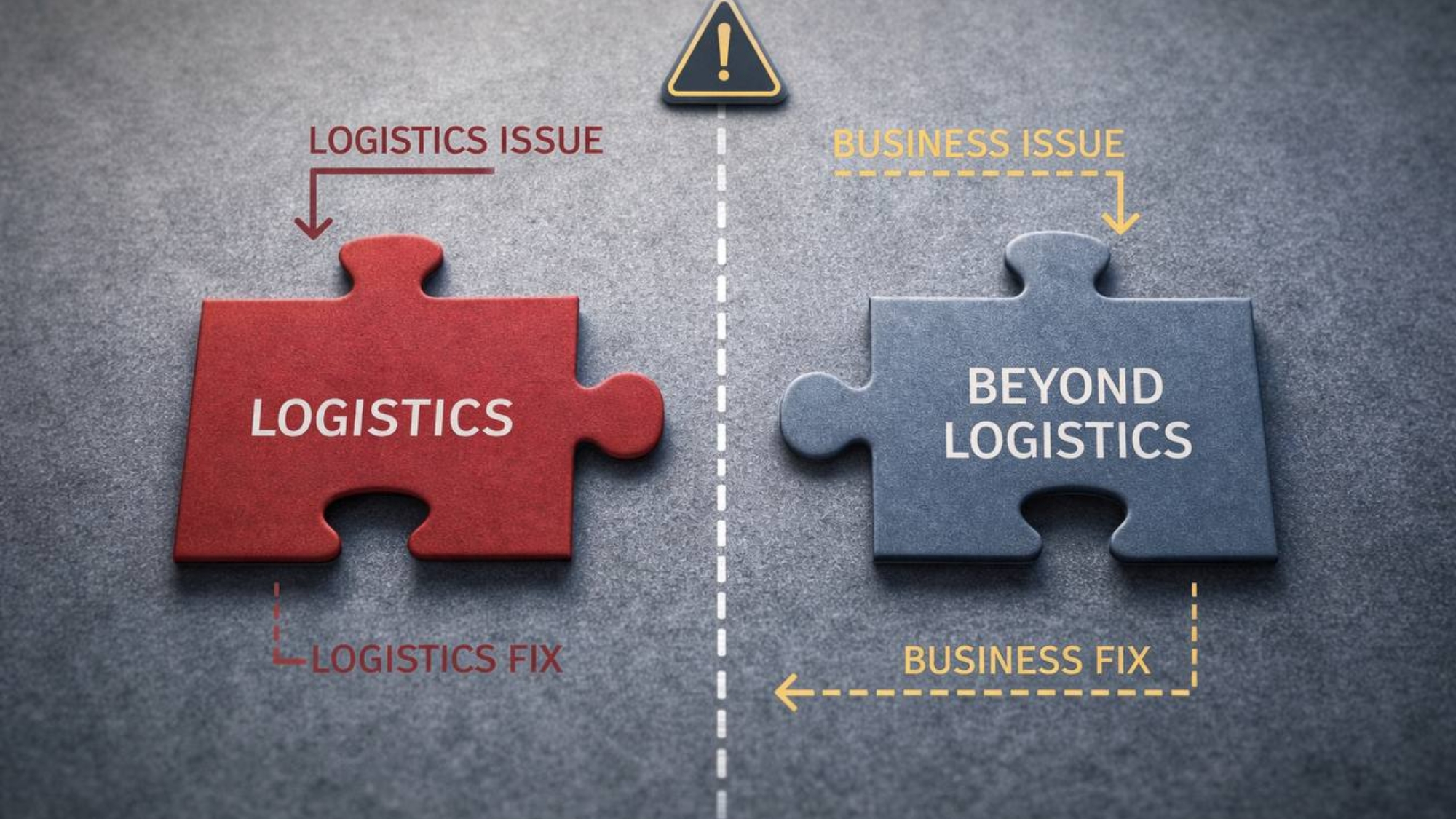

The issue with blurred responsibility is not workload alone. It is signal loss. When logistics absorbs problems silently, the organization stops seeing where friction truly originates, a pattern RoadFreightCompany encounters frequently in complex European freight networks. Warehouse constraints look like transport delays. Commercial overcommitment looks like capacity unreliability. Structural misalignment is mistaken for execution weakness. Over time, improvement efforts target the wrong areas.

This dynamic also affects relationships. Partners receive mixed signals. Carriers are asked to solve issues they did not create. Warehouses experience fewer consequences for rigid processes. Commercial teams continue selling promises that logistics quietly adjusts to. From the outside, it appears that logistics is “handling it.” Internally, pressure accumulates.

Some organizations are starting to redraw these boundaries more deliberately. They do not escalate everything, but they stop automatically compensating. They clarify which issues logistics can fix, which require coordination, and which must be addressed at design level. Where this happens, short-term discomfort often appears – followed by longer-term stability.

Road Freight Company sees that networks with clear responsibility lines tend to improve faster, even if they initially feel less smooth. Problems surface where they belong. Conversations become more specific. Decisions are made closer to their source. Logistics execution becomes lighter because it is no longer carrying the weight of the entire system.

The key insight is that strong logistics is not about absorbing friction endlessly. It is about knowing when to act and when to expose. In European road freight, where complexity is unavoidable, clarity of responsibility becomes a form of efficiency in itself. Teams that respect these boundaries not only reduce stress – they make improvement possible.